Custom Industrial Packaging Solutions – Ensuring Safe and Efficient Delivery of High-Value Industrial Products

Get you Free Consultation Today!

Are you experiencing any of these challenges?

- Struggling to find suitable packaging for non-standard product sizes?

- Current packaging is non-collapsible, resulting in high empty return and storage costs?

- Packaging is easily damaged and not reusable?

- Packaging is too heavy, making it difficult to handle?

The demand for industrial custom packaging solutions has never been higher in today’s fast-paced market. Businesses across various industries seek innovative ways to enhance product presentation and ensure safety during transportation, especially for the automotive industry. At Tecpack, we specialize in providing comprehensive industrial custom packaging solutions and sustainable, reusable, and returnable packages that cater to our clients’ unique needs.

The Application of Modular

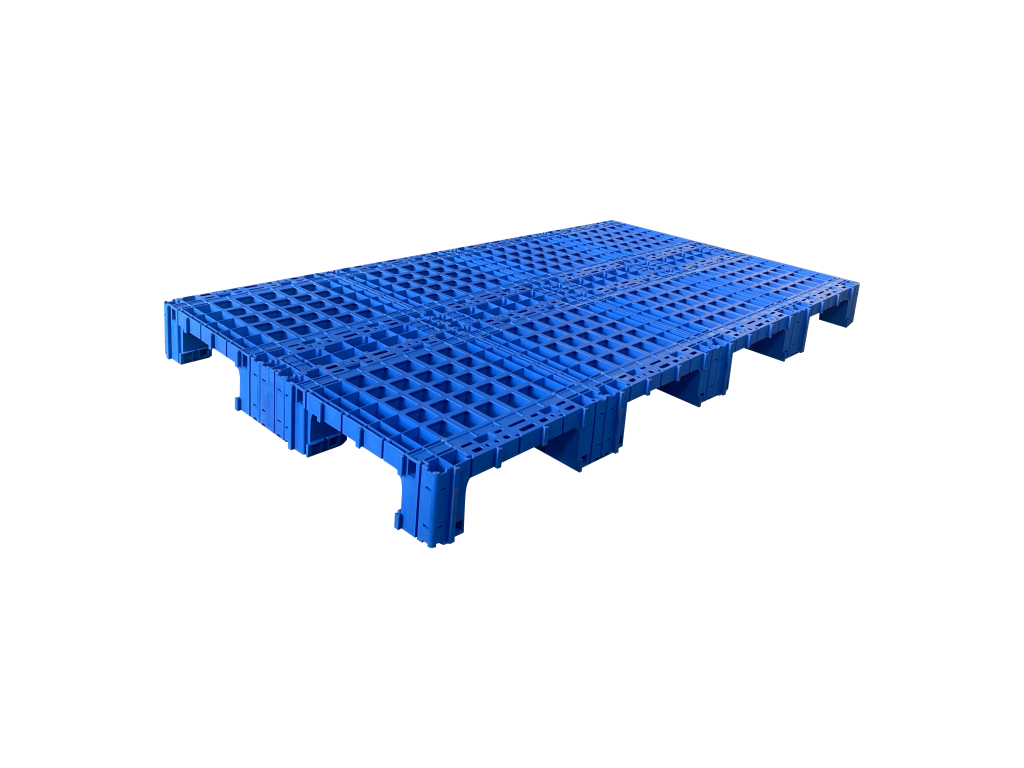

Modular Plastic Pallets are a type of plastic pallets that flexible on any sizes. They are constructed from injection-molded plastic pallet modules that interlock internally and are reinforced with steel pipes to form a single, cohesive pallet.

Modular interlocking Pallets are primarily used to address scenarios where standard-sized plastic pallets are inadequate, such as for pallets exceeding 2000mm or for ground coverage in warehouses.

Modular pallets are high-quality innovative industrial packaging designs and reusable flexible Packaging Solutions.

Blow-Molded Container Boxes

The greatest advantage of TECPACK is its ability to assist customers in designing and customizing innovative reusable packaging solutions.

TECPACK can help clients customize injection-molded boxes, blow-molded container boxes, thermoformed container boxes, as well as various thermoformed trays, non-woven fabrics interior packaging materials, brushed nylon soft packaging, corrugated dividers, EPP trays,etc.

Tecpack can offer eco-friendly and sustainable packaging solutions.

Blow-Molded Container Boxes

The greatest advantage of TECPACK is its ability to assist customers in designing and customizing innovative reusable packaging solutions.

TECPACK can help clients customize injection-molded boxes, blow-molded container boxes, thermoformed container boxes, as well as various thermoformed trays, non-woven fabrics interior packaging materials, brushed nylon soft packaging, corrugated dividers, EPP trays,etc.

Tecpack can offer eco-friendly and sustainable packaging solutions.

TECPACK’s metal frame boxes

Unlike traditional metal cages, TECPACK’s metal frame boxes feature a honeycomb sheet structure for the main body, with honeycomb panels used for the sidewalls and base. The bottom and lid are reinforced with steel pipes or plates, and the base is supported by plastic feet. This bespoke packaging design makes the boxes lightweight and cost-effective, making them an excellent cost-effective packaging choice for lightweight transportation and storage.

Aluminum alloy frame boxes

Due to its lightweight nature and resistance to rust, aluminum alloy is often used to complement and replace metal frame boxes, making it an ideal packaging materials for the storage and transportation of lightweight goods.

Are modular pallets and boxes sturdy?

How much does it cost to customize injection-molded box molds?

How much does it cost to customize blow-molded and thermoformed box molds?

What is the typical processing time for custom packaging molds?

The Importance of Sustainable Packaging

As environmental concerns grow, businesses are turning to sustainable packaging solutions. Recyclable packaging not only meets consumer demand for eco-friendly options but also helps companies reduce their carbon footprint. By incorporating circular packaging principles, businesses can create a closed-loop system that minimizes waste and promotes reuse.

Circular Packaging Explained:

Design for Reuse: Packaging should be designed to be reused multiple times, extending its lifecycle.

Recycling: Encourage customers to recycle packaging materials after use, contributing to a sustainable ecosystem.

Material Recovery: Implement systems to recover materials from used packaging, ensuring they are reintroduced into the production cycle.