In the supply chain logistics of auto parts, packaging equipment is required to provide support, fixation, and protection for products to avoid scratches, deformations, breaks, and drops during transportation, loading and unloading, and distribution. The purpose of packaging equipment is to protect parts. Whether its planning and design are scientific and reasonable has a significant impact on the efficiency of parts in the supply chain. Therefore, the equipment plays an important role in the transportation and storage of auto parts.

With the rapid development of China’s auto industry, the auto parts industry has become increasingly prosperous. As a necessary part of the transportation and storage of parts, the demand for packaging is also increasing day by day. According to statistics, traditional fuel vehicles require more than 1,200 types of components for packaging planning, and plug-in hybrid vehicles require more than 1,500 types. This poses a huge challenge to the planning and design capabilities of packaging equipment service providers.

A logistics expert from SAIC stated that “the key to determining whether a packaging service provider has integrated service capabilities is packaging planning.” At present, Zhongjiu Technology and Lianming Packaging have the ability to extend to packaging planning. For example, Lianming Packaging has completed more than 120 complete vehicle packaging planning projects for well-known vehicle manufacturers such as SAIC-GM.

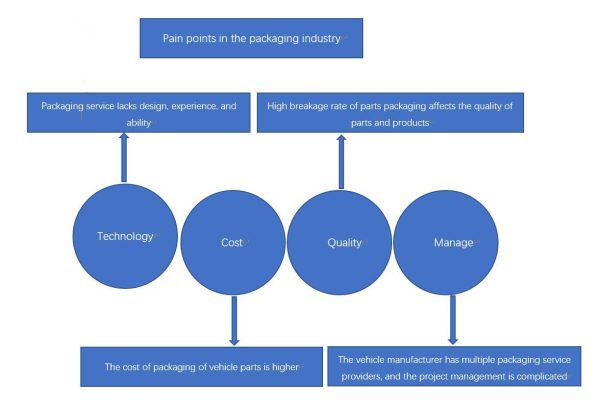

According to a packaging expert from Zhongjiu Technology, “In the auto parts packaging business, there are still some industry pain points that need to be solved urgently. Specific attributes, there is no system in the maintenance of appliances, etc.”. A logistics planning expert of BAIC New Energy also said that “service providers’ familiarity with auto parts needs to be improved. Whether they have planning, design experience, and application cases is a key factor for vehicle manufacturers to consider service providers.”

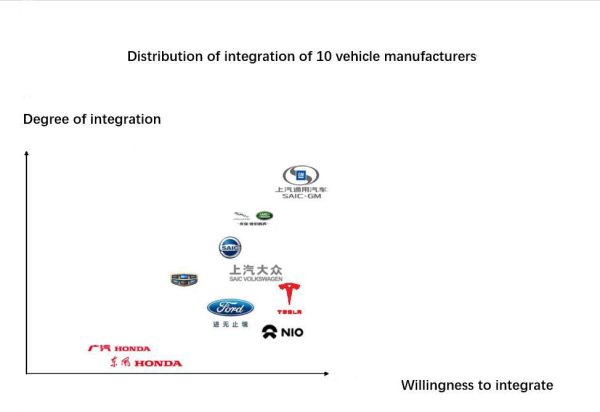

Currently, most OEMs still hold the lead in packaging planning. However, with changes in the structure of the automotive industry chain, vehicle manufacturers have gradually outsourced non-core businesses to focus on key technologies and reduce costs. In the long run, the “integration” of auto parts packaging has a very broad application space in the parts packaging business.

As a logistics expert of a vehicle manufacturer mentioned, “Packaging equipment service providers need to develop packaging equipment just like vehicle manufacturers develop auto parts.” The packaging integration model has solved the packaging business problems faced by vehicle manufacturers to a certain extent. It will become the main development direction of the packaging business of vehicle manufacturers in the future.

As a professional manufacturer of auto and motorcycle parts, Qingdao Huading Industry Co., Ltd. provides professional solutions and is committed to warehousing and logistics technology to make auto parts packaging no longer difficult.

Thanks for reading! If you’ve enjoyed this article, it would mean a lot to me if you shared it!