Batteries are an important part of electric vehicles (EV) and are very sensitive to high mechanical loads (such as collisions).

Due to the large differences in the structure and types of new energy vehicles, there are also obvious differences in the battery pack structure as the core of new energy vehicles.

Today, players in the electric vehicle industry are working on optimizing battery packs designs. With our versatile TECPACK solutions, we offer a wide range of material options for kinds of designs, enabling most Li-ion battery packaging designs involving cylindrical, pouch or square automotive battery types. The result: improved EV batteries storage and safety, reduced weight and costs.

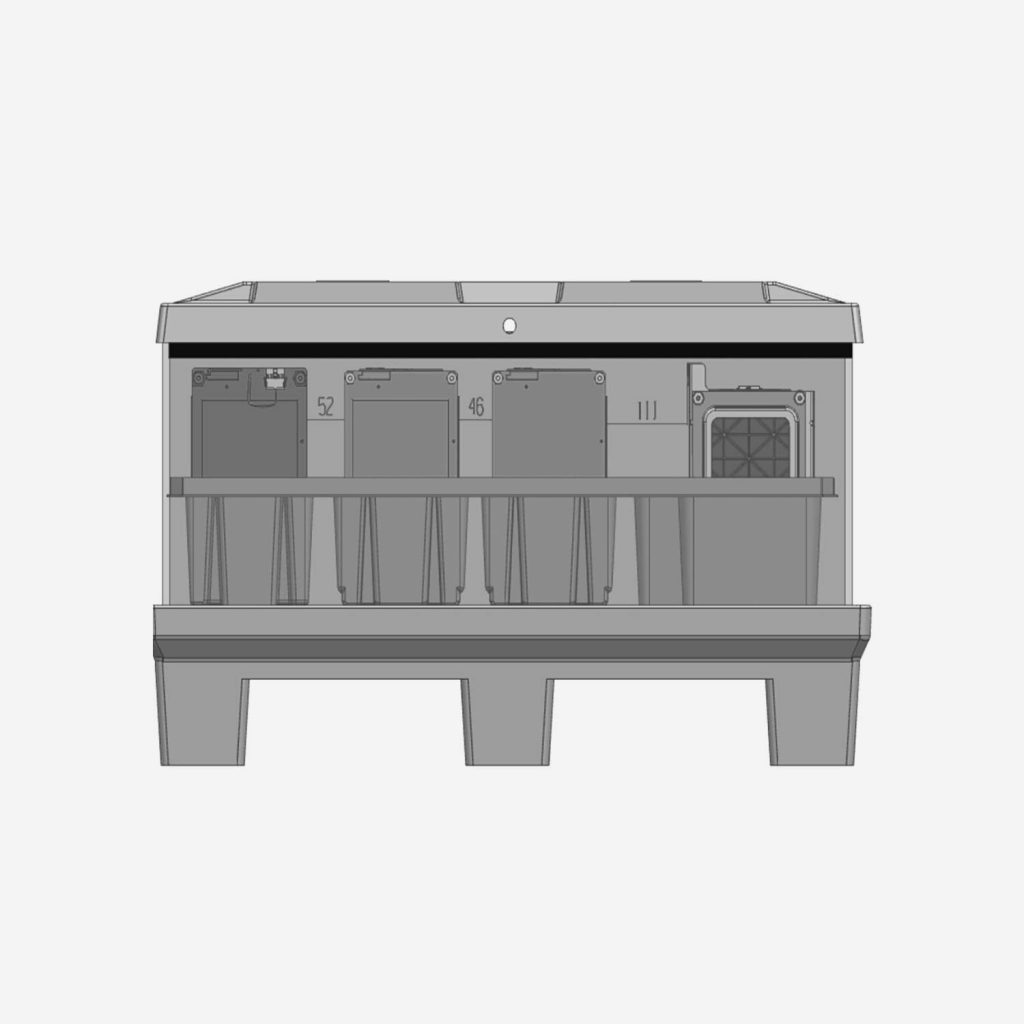

TECPACK team optimized the assembly strategy and positioning scheme based on the characteristics of Motor’s new energy batteries.

TECPACK used a customized blister pallet to limit the new energy lithium batteries very tightly, no more spaces, which avoids battery shaking that might withstand impact during transportation, At the same time, the standard sleeve boxes 1200×1000 (48*40″”) are used as an outside package, so they are suitable for various types of transportation.