July 11, 2022 UL Solutions, one of the global leaders in applied safety science, today introduced the Battery Enclosure Thermal Runaway (BETR) evaluation product, which UL Solutions uses to evaluate the automotive component packaging material for electric vehicle (EV) battery enclosures The first materials screening test method. This product is based on UL 2596 technology (Test Methods for Thermal and Mechanical Properties of Battery Housing Materials) published by UL standards and participating organizations on January 27, 2022.

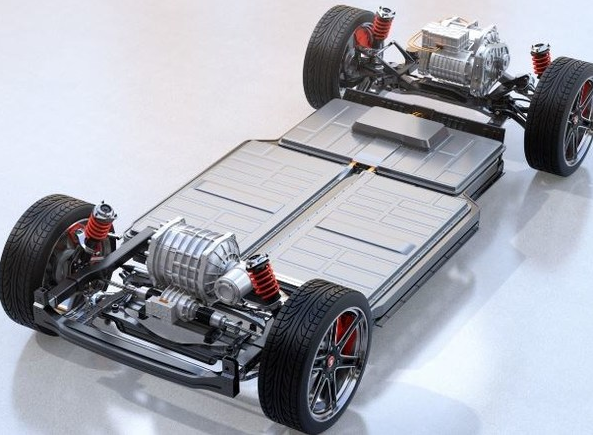

Battery performance continues to present challenges in electric packaging automotive energy efficiency. Electric vehicles have higher vehicle weights due to heavy battery systems, which means more frequent charging and shorter driving times. However, the battery housing system plays a key role in mitigating the effects of thermal runaway, a risk associated with packaging lithium batteries. Thermal runaway occurs when a lithium-ion battery enters an uncontrolled self-heating state that can cause fires, smoke and extreme heat, while ejecting harmful particles.

“As e-mobility continues to grow, thermal runaway has become a critical safety issue in the packaging automotive industry, further raising awareness about how to use the best housing materials for thermal runaway,” said Eric Bulington, director of product management, Engineered Materials, UL Solutions. Conservation concerns. Through this service, we are helping manufacturers address one of the most complex challenges in the electric vehicle industry, while meeting the market demand for innovative and trusted automotive products.”

UL Solutions test methods evaluate material performance by simulating thermal runaway scenarios. Evaluation involves testing small pieces of material versus the entire battery assembly, reducing testing costs and development time for resin manufacturers and material suppliers. The evaluation also focuses on screening multiple formulations during the R&D process, giving material producers the opportunity to provide original equipment manufacturers (OEMs) with solutions that meet their needs while considering various material properties.

“UL Solutions has a long history of thought leadership in battery technology of all shapes and sizes, so we are well positioned to continue our legacy in electric vehicle batteries,” Bulington said. Manufacturers and suppliers, automotive component and system manufacturers provide testing and consulting solutions to solve industry problems to meet multiple standards and regulatory requirements.”